MULTI CIRCUIT: Ejectors with 4, 5, 6 or 8 independent vacuum circuits – clearly arranged, cost-effective and compact

Brief Description:

The MULTI CIRCUIT ejectors are available with up to 8 independent vacuum circuits, which are combined in a small housing in a very space-saving and very compact way. This enables a very quick and clear installation, simplifies assembly and saves a lot of time. Com-pared to the use of conventional ejectors, much fewer components (tubes, cables, fittings, sensors, system inputs) are required, thus reducing the purchase costs.

The blow off process for all vacuum circuits is started centrally via a common signal. Both, air operated blow off as well as solenoid operated blow off is possible. When several MULTI CIRCUIT ejectors are connected in series, a combination as well as a master/slave function is possible.

Even if not all suction cups are in contact with the object (e.g. differently shaped parts), the remaining suction cups still generate vacuum and the object can be lifted. The AMS system is able to monitor all vacuum circuits using just one sensor.

Please see new documentation (add this new catalog link here) for all new updated features.

Advantages:

- Fast and simple installation

- 4 to 8 independent vacuum circuits

- AMS monitoring system: only 1 sensor for vacuum monitoring of all circuits

- Increased safety: also possible with vacuum holding valve

- Economical: electronically operated compressed air supply valve possible

- Cost-effective: fewer components save on assembly and purchase

BOOSTER RELEASE: Ejectors for applications with extremely fast cycles

Brief Description:

The BOOSTER RELEASE ejectors are equipped with a unique, paten-ted, extremely fast blow off system, ideal for applications with very short cycle times.

For blow off, a jet nozzle is activated by a solenoid valve, which redirects the compressed air flow to the vacuum connection. In addition to the compressed air flow through the pressure connection and the jet nozzle, air is now sucked in from the environment through the exhaust. This additional environmental air flow decreases as the vacuum level decreases. Thus, the object is released very quickly but still gently and in a controlled manner.

When installed locally directly on the vacuum lifter, the low weight and compact design allow the ejector to be used as a suction cup mounting. The easy installation and small tube dimensions result in low installation costs.

Please see new documentation (add this new catalog link here) for all new updated features.

Advantages:

- Extremely fast: for very short cycles

- Very compact and light: ideal for installation directly on the suction cup

- Ejector can be used as suction cup mounting

- Very robust and durable: designed for up to 100 million operation cycles

2BV AIR SAVE: Vacuum ejector with automatic air saving function – allows approx. 95% energy savings

Brief Description:

2BV AIR SAVE ejectors are equipped with an integrated vacuum control circuit. When the factory-set upper vacuum level of -0.75 bar is reached, it shuts off the air supply. If the vacuum drops to the lower set value of -0.65 bar due to leakage, the air supply is automatically restarted. This enables a significant compressed air saving of approx. 95%! The lower vacuum threshold value can be very easily changed by ± 10% via an adjusting screw on the ejector.

The object to be transported is quickly and safely released by a blow off impulse. The blow off valve already opens from 0.5 bar. The 2BV AIR SAVE ejector also has a measuring connection for vacuum monitoring by an external sensor.

Due to the integrated full pneumatic vacuum control circuit no external control system is required. The ejector can be installed quickly and easily. This saves additional money on purchase and installation.

Please see new documentation (add this new catalog link here) for all new updated features.

Advantages:

- Automatic air-saving function: saves over 95% of compressed air

- Integrated vacuum control circuit: no external control system required

- Integrated holding valve and blow off valve: double safety against unintentional release

AUTOVAC MFE: Programmable multifunction ejector with automatic air-saving function – available in 4 sizes

Brief Description:

The AUTOVAC MFE is a smart vacuum generator that has been specially designed to meet the requirements of Industry 4.0. The intelligent plug-and-play ejector can be used very flexibly and, with its integrated, programmable automatic air-saving function, offers an air-saving potential of more than 95% (depending on the application). The built-in holding valve delays the release of the object in case of pressure drop. The MFE ejectors are available in 4 sizes and in the versions NC (Normally Closed) and NO (Normally Open).

By means of various feedback options, wear and tear, e.g. of suction cups, hoses or connections, can be detected at an early stage, even before the system fails. Expensive downtimes can thus be avoided.

Please see new documentation (add this new catalog link here) for all new updated features.

Advantages:

- Variably configurable: programmable vacuum and blow off functions

- Increased process safety: preventive maintenance functions

- Integrated air-saving automatic

- Higher safety in case of pressure drop: built-in holding valve

BASE EJECTORS: Basic, cost-effective standard vacuum ejectors

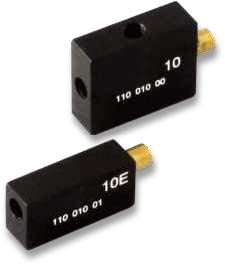

MINI Ejectors

The very small and light MINI ejectors are used where small and light objects are handled and very tiny installation dimensions are important. They are particularly used in the production of electronic components.

With a supply pressure of only 4 bar the MINI ejectors can generate a high vacuum of more than 85%. They are available with and without mounting thread.

ORIGINAL Ejectors

The ORIGINAL ejectors generate a high vacuum of more than 85%already at 4 bar compressed air sup-ply. The very low supply pressure required made these ejectors very efficient in terms of energy consumption.

The RR connection can be used for controlled blow off of the object or to connect a vacuum sensor. If the RR connection is not required, it can be closed with the plug supplied.

INLINE Ejectors

The ORIGINAL ejectors generate a high vacuum of more than 85%already at 4 bar compressed air sup-ply. The very low supply pressure required made these ejectors very efficient in terms of energy consumption.

The RR connection can be used for controlled blow off of the object or to connect a vacuum sensor. If the RR connection is not required, it can be closed with the plug supplied.

Other Products – Solenoid Operated Ejectors & EJECTORS with vacuum holding valve

MV Ejectors

Solenoid operated ejectors in four sizes with one integrated solenoid valve for vacuum generation.

MV-MV Ejectors

Solenoid operated ejectors in three sizes with one integrated solenoid valve for vacuum generation and one for a controlled blow-off offering a minimum response time with greater accuracy

2BV

The compact, lightweight 2BV ejectors are ideal for handling non-porous materials such as metal or glass. Energy savings of more than 95% are possible when using an appropriate control system. The blow off valve already opens from 0.5 bar, so several 2BV ejectors can be operated with the same blow off pulse.

AUTOVAC Ejectors

The AUTOVAC series are available in three sizes and offers air savings in combination with an appropriate control system and a vacuum switch. Air savings of >95% are achievable for air tight materials.